18M/min Z axis High Speed Jumping

Core Technology of Automated Electrical Discharge Machine

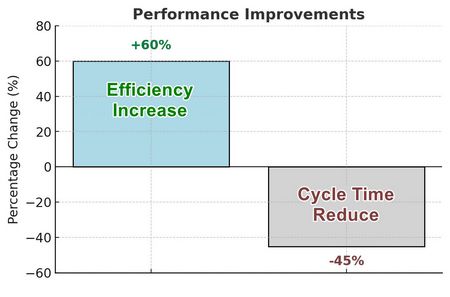

The new AE II motion control algorithm, by using Ether CAT digital signal transmission, delivers Z-axis high-speed jumping up to 18M/min. Rivals linear motor systems, especially suit for deep-hole machining. Even when handling deep-hole or large-area precision machining, it effectively clears machining debris quickly to ensure stable processing quality.

Machining Case Study

EtherCAT Servo Drive Technology

The new AE II motion control algorithm, by using EtherCAT digital signal transmission, delivers Z-axis high-speed jumping up to 18 M/min. Rivals linear motor systems, especially suit for deep-hole machining.

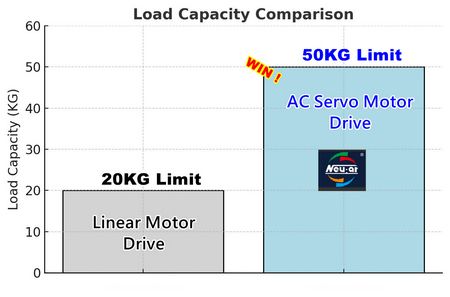

Better Than Linear Motor Drives

Linear motors are limited by weight restrictions due to magnetic core, unsuitable for heavy electrodes. NEUAR using ball screw structure can support more heavier load electrodes, ensuring reliable and safe machining.

18M/min Z axis High Speed Jumping | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction