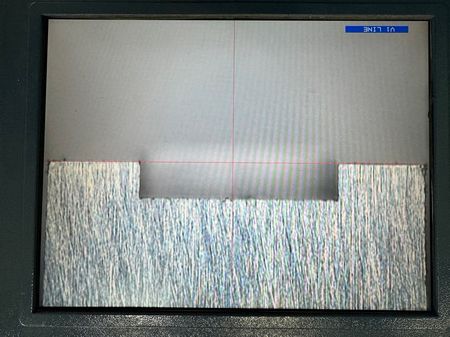

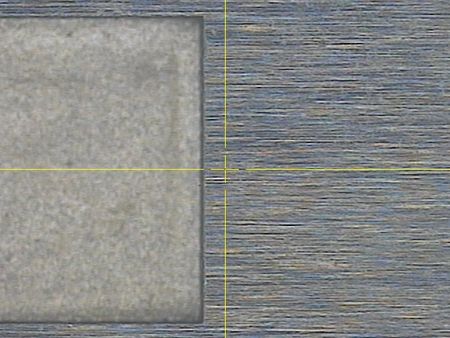

Corner Radius of cavity within 4um, for Connector Mold

Core Technology of High-Speed Mirror Electrical Discharge Machine

As electronic products continue to evolve toward higher precision and miniaturization, machining demands are becoming increasingly stringent. For fine structures, NEUAR’s latest wear-suppression technology delivers exceptional performance with a minimum corner radius as small as 5 μm, making it especially well-suited for the precision electronic connector industry.

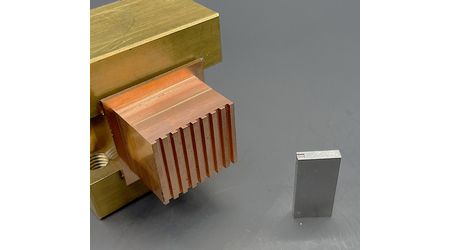

Machining Case Study

Ultra-Low Wear EDM Technology + Micro Discharge Circuit

Equipped with AE II "Low-Wear Circuit (LW2)" and "Micro Discharge Circuit (MG)", enabling ultra-small corner R radius machining.

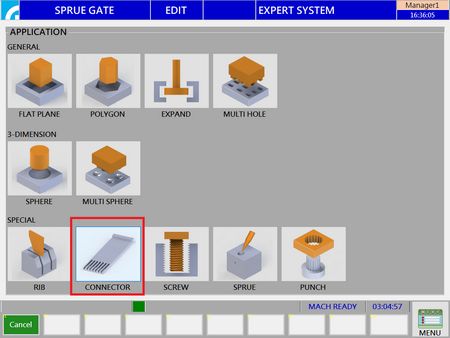

Expert system Connector modules

- Built-in specialized machining condition packages automatically provide the optimal solution based on different requirements:

- Intelligent suggestions for suitable corner radius (R) and number of electrodes.

- Automatic selection of optimal machining parameters — no manual setup needed.

- Auto-generation of displacement coordinates for precise and efficient processing. When combined with the ATC system, it can efficiently handle multiple machining positions.

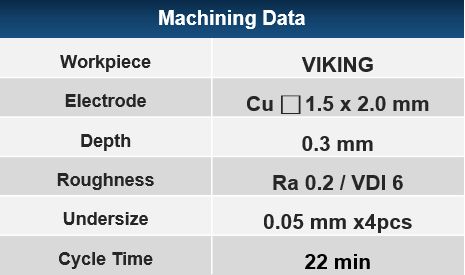

Machining Case Study: Connector mold machining data

Corner Radius of cavity within 4um, for Connector Mold | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction