Intelligent Expert System

Expert System for Automated Electrical Discharge Machine

New AEII discharge power system breaks through old machining limits. Extensive experience is not required, even beginners can easily edit machining program through AEII expert system. 5 simple steps to make you become an EDM expert !

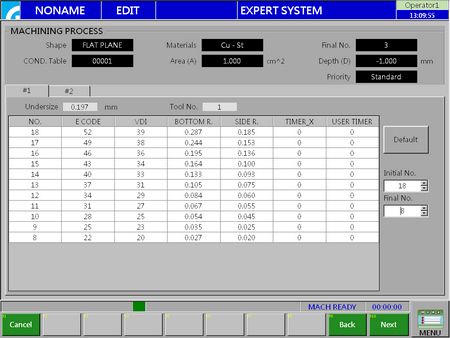

Expert System Operation Steps

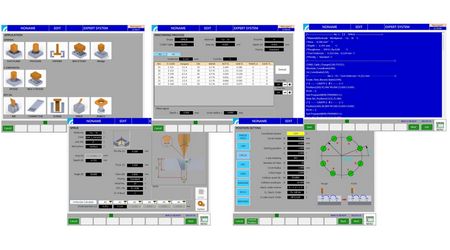

Step 1 : Select electrode shape

Abundant machining application modes

Database with variety of electrode application modes : RIB, CONNECTOR, SCREW ,SPRUE, 3D SPHERE and so on, it is enough for a variety of complex machining tasks.

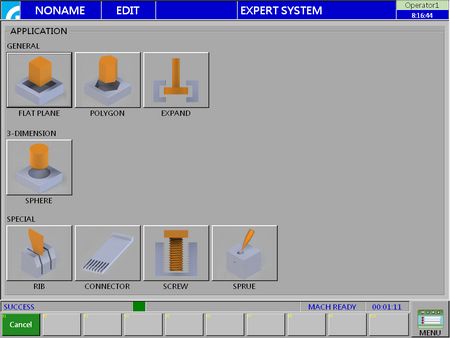

Step 2 : Input machining parameter

Automatically select the best undersized calculation and number of electrodes

Simple understanding parameter setting interface.

Just enter machining parameters, the internal calculation engine can calculate the most appropriate electrode undersize and number of electrodes.

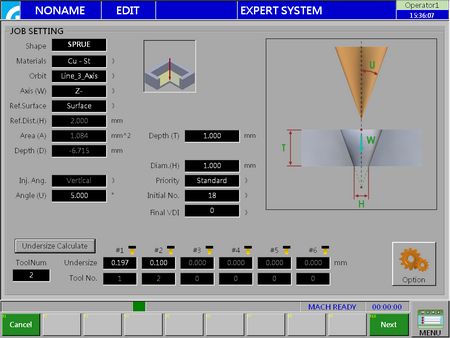

Step 3 : Preview of maching program

Machining program of each electrode can be adjusted at will

All electrode machining procedures are clearly presented.

Based on past machining experience, user also can flexibly adjust the procedures, allowing you to experience highly flexible machining capabilities of AEII expert system!

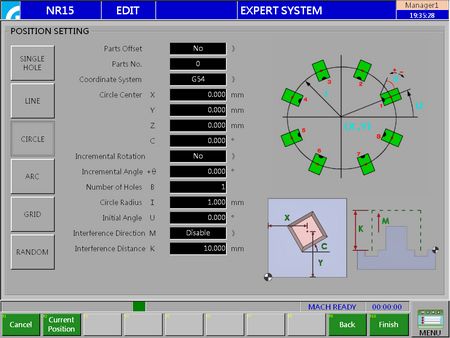

Step 4 : Machining process & position setting

Interference avoidance function of position and coordinate system rotation offset

Built-in 60 sets of machining coordinate system, 50 sets of workpiece coordinates, it can cope with multi-hole, multi-workpiece machining tasks. With the coordinate system of workpiece offset , users no longer have to worry about large workpieces offset, saving calibration time on site.

Step 5 : Generating machining program completed!

Interchangeable : GM code < = > Dialogue Code

Exclusive creation of multi-language machining code, improvement of shortcomings of traditional GM codes that are not easy to understand visually.

After the program code generated by system is saved, you can start machining with one click, which is easy and effortless!

Intelligent Expert System | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction