Depth -53mm deep hole mirror surface machine

Core Technology of High-Speed Mirror Electrical Discharge Machine

In the EDM industry, achieving a mirror surface finish often requires adding powder to the dielectric fluid. However, NEUAR’s Electrical Discharge Machine utilize advanced mirror-finish discharge circuit technology that achieves an ultra-fine surface roughness of Ra 0.08 µm—without the need for any powder additives. This innovation not only enhances machining efficiency but also significantly reduces the time and cost of post-processing, delivering exceptional economic benefits to users.

Machining Case Study

No more Polishing required

NEUAR specializes in mirror surface technology. Through optimized power control and discharge parameter tuning, the new system features the second-generation “HQM2 – Hyper Quality Mirror Circuit,” which eliminates uneven reflection issues and achieves uniform and stable machining results. For mirror surface requirements in plastic molds, this technology eliminates the need for manual polishing, allowing molds to be used directly on machines.

Whether facing the challenges of intricate textures or pursuing the highest surface quality, our mirror EDM technology meets your most demanding requirements—offering a reliable and efficient solution for precision manufacturing and helping customers create highly competitive products.

Ultra Low Wear Control

The ultra-low wear control technology ensures the finishing electrodes almost no wear, keeping edges and corners sharp and distinct.

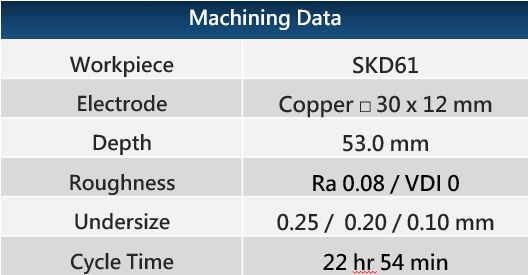

Machining Case Study : deep hole mirror surface machining

Depth -53mm deep hole mirror surface machining , plastic mold no more polishing

Depth -53mm deep hole mirror surface machine | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction