High-speed Tungsten Carbide Internal Threading

Core Technology of High-Speed Mirror Electrical Discharge Machine

When machining ultra-hard tungsten carbide using traditional CNC milling, tool wear is typically very high, resulting in significant cost. However, by using EDM technology, tool wear can be drastically reduced. NEUAR's latest AEII EDM technology significantly shortens discharge time for tungsten carbide thread machining. Unlike traditional methods that require at least two electrodes to machine internal threads in tungsten carbide, the SH2 model equipped with the "Super Hard Tungsten Carbide Circuit" enables completion of internal threading with just one electrode.

Machining Case Study

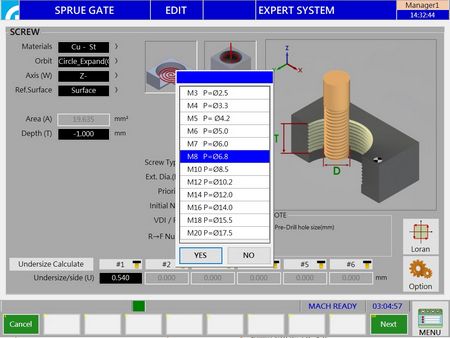

Auto-calculates Required Loran Radius

For M3~M20 metric threads, simply select the size. NEUAR EXPERT system automatically calculates the optimal Loran radius based on electrode wear, whether for tungsten carbide or pre-hardened steel.

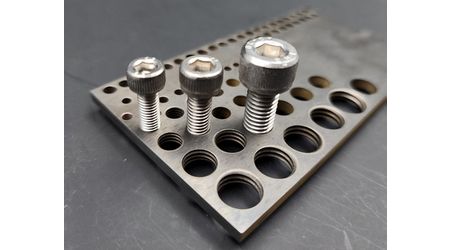

Using Just Only ONE Electrode

NEUAR all CNC series equipped with "Super Hard Tungsten Carbide Circuit (SH2)" ensures the screw fits tightly by using only ONE electrode.

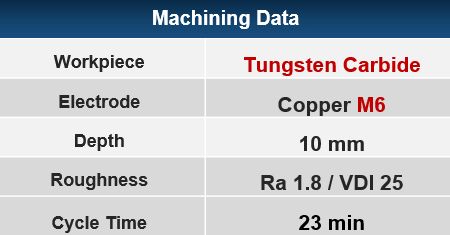

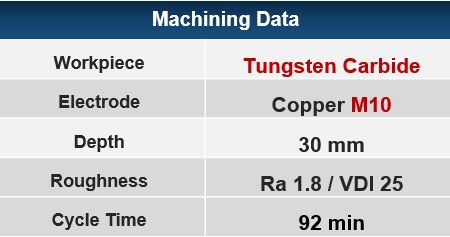

Machining Case Study: Tungsten Carbide M6/M10 Internal Thread Machining

With just one copper electrode, even ultra-hard tungsten carbide materials can be machined—eliminating the need for alignment using two electrodes.

The low-wear EDM technology ensures efficient processing time while maintaining a secure, wobble-free screw fit inside the threaded hole.

High-speed Tungsten Carbide Internal Threading | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction