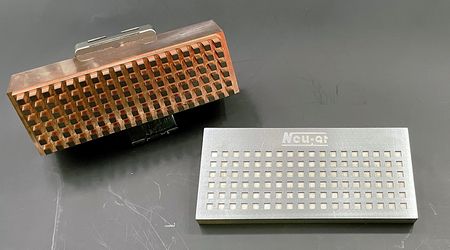

144 Cavities of Semiconductor Packaging Mold

Core Technology of Automated High-Speed Electrical Discharge Machine

With the rapid development of the semiconductor industry, electronic products are evolving toward higher capacity, greater density, and lighter designs. Packaging solutions are also trending toward multi-lead configurations, thinner profiles, and finer lead pitches. As product designs become more compact, tolerances continue to tighten, placing increasingly stringent demands on manufacturing precision. The 144-cavity semiconductor packaging mold sample exemplifies a uniformly fine and consistent surface finish that meets these high-precision requirements.

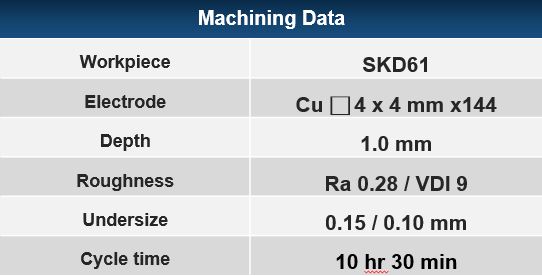

Machining Case Study

Precision multi-cavity machining technology to meet the demands of the semiconductor industry

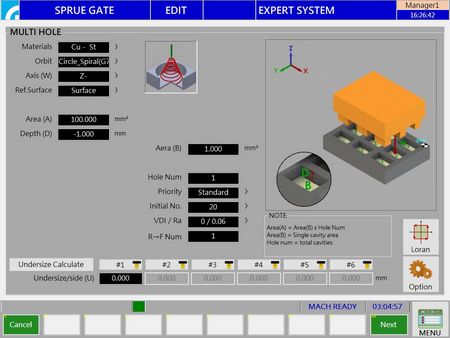

In large-area or multi-cavity packaging mold applications, surface roughness consistency and dimensional accuracy are critical factors affecting the flatness of the final product. NEUAR’s expert system provides a dedicated machining program for multi-cavity processing using a single electrode with identical shapes. This ensures uniform surface texture and outstanding precision for each cavity, perfectly meeting the high standards of the semiconductor industry.

Depth error within 3μm across 144 cavities

Achieve high-precision machining with consistent surface roughness and depth across all cavities.

Simple Operation, Rapid Generation of Multi-Cavity Mold Machining Programs

Even with no IC packaging machining experience, operators can quickly generate machining programs using build-in application module. The intuitive system design significantly lowers the learning curve, making machining more efficient and convenient to meet various IC packaging requirements.

144 Cavities of Semiconductor Packaging Mold | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction