New AE II discharge power system breaks through old machining limits, which means faster cycle time, better surface finish, and lower electrode wear.

Z axis fast jumping speed 18M/min

The new AE II type motion control algorithm improves debris removal speed. The spindle can reach high-speed movement of 18M/mm to remove debris, which is nearly 9 times faster than the original AI model. In large-area and precision machining discharge occasions, stable servo motion control is provided to improve discharge efficiency and shorten machining time.

Workpiece

| Item | Content |

| Electrode | Graphite POCO EDM 2 |

| Workpiece | SKD 11 |

| Projection area | 1 x 38 mm |

| Machining depth | 70 mm |

| Surface roughness | VDI 25 / Ra 1.8 um |

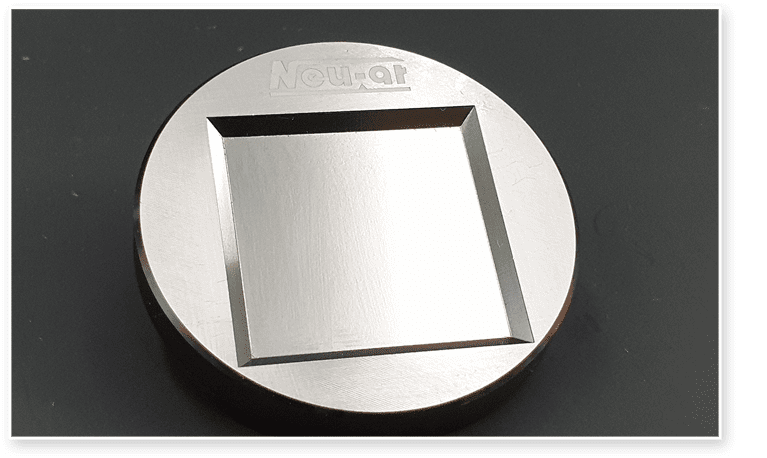

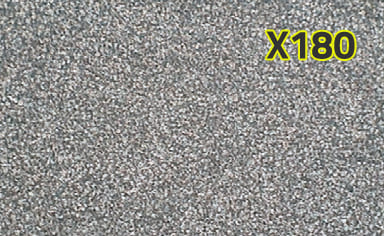

Mirror surface Ra 0.08um

The ultra-fine surface Ra 0.08 um can be easily reached even in a large area without using powder technology, saving time for further polishing treatment.

Workpiece

| Item | Content |

| Electrode | Copper |

| Workpiece | NAK 80 |

| Projection area | 35 x 35 mm |

| Machining depth | 1.97 mm |

| Machining time | 5 hours 15 minutes |

| Surface roughness | VDI 0 / Ra 0.08 um |

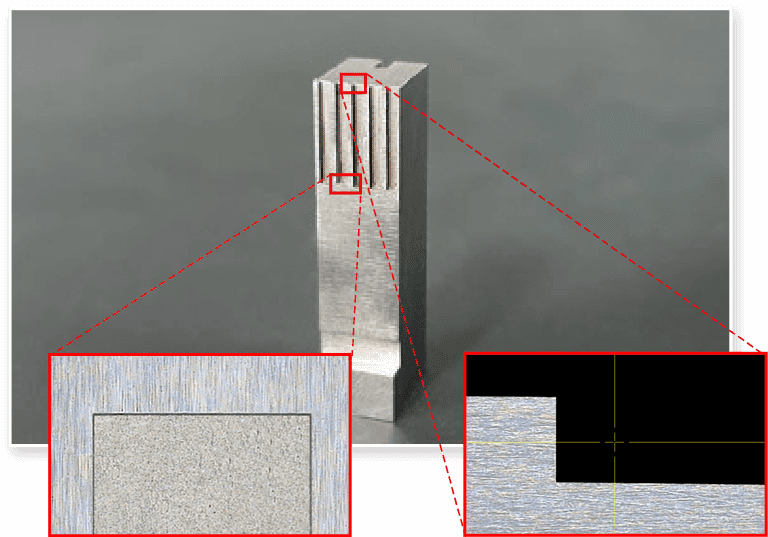

Sharp corner R radius 8um

As electronic products move toward high-precision and miniaturization, the requirement standards for machining are getting higher and higher. For finer lines and shapes, through the latest wear suppression technology, the best R angle 8um can be achieved.

Workpiece

| Item | Content |

| Electrode | Copper |

| Workpiece | VIKING |

| Undersized calculation | 0.05 mm |

| Number of electrodes | 4 |

| Machining depth | 0.3 mm |

| Surface roughness | VDI 7 / Ra 0.22 um |

Super harden material machining

The high tool wear caused by super hard materials is a major problem in electrical discharge machining. Through a new exclusive super hard alloy circuit and low wear technology , the sharp corner R radius can be clearly displayed. The best surface roughness can reach up to Ra 0.22 um.

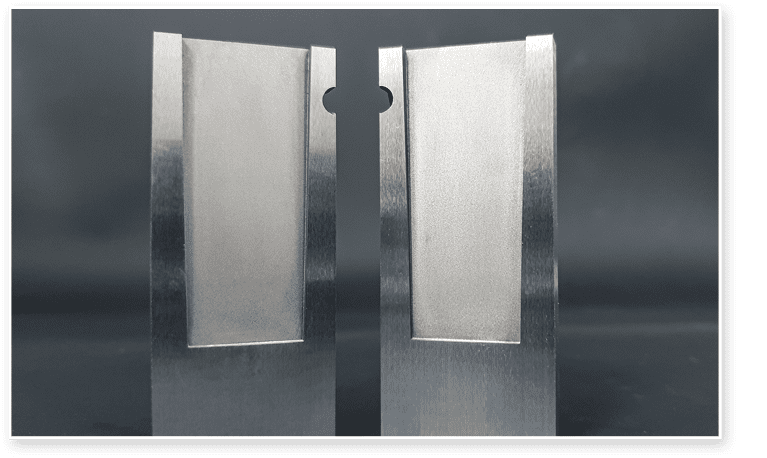

Workpiece

Previous technology

AE II New technology

| Item | Content |

| Electrode | Copper Tungsten |

| Workpiece | Tungsten-Carbide HRA 90° |

| Projection area | 83 mm2 |

| Machining depth | 0.15 mm |

| Machining time | 2 hours 10 minutes |

| Surface roughness | VDI 7 / Ra 0.22 um |

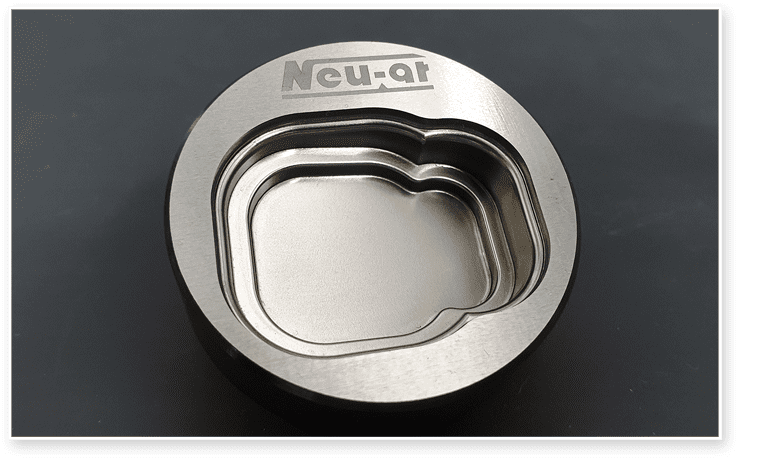

Fine finishing machining

Newly developed discharge power circuit, significantly fine finishing machining performance improved , compared with the previous generation, cycle time reduced by nearly 45%.

Workpiece

| Item | Content |

| Electrode | Copper |

| Workpiece | NAK 80 |

| Projection area | 38 x 28 mm |

| Machining depth | 12 mm |

| Machining time | 6 hours 9 minutes |

| Surface roughness | VDI 9 / Ra 0.28 um |

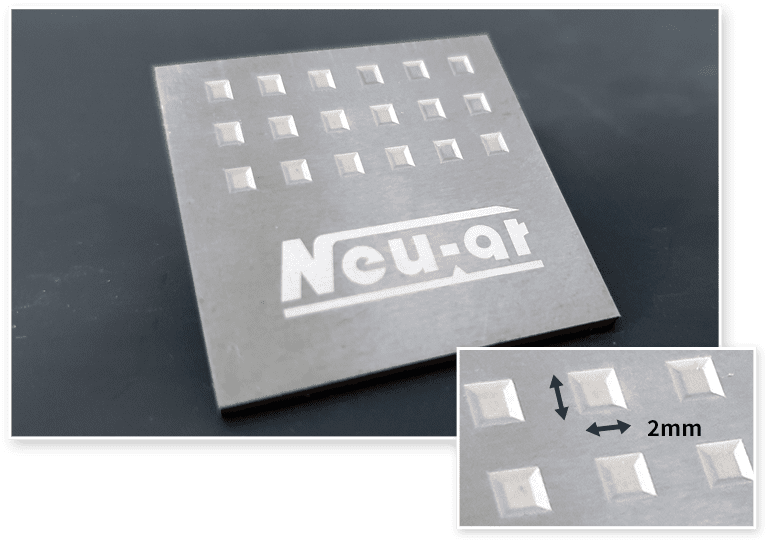

Large area machining technology

The larger the workpiece area and the finer the surface, the more uneven particles will appear. The new AE II power supply, through monitoring high-speed discharge gap state , can result an even machining surface, improving the efficiency, and greatly reduce the subsequent mold polishing time.

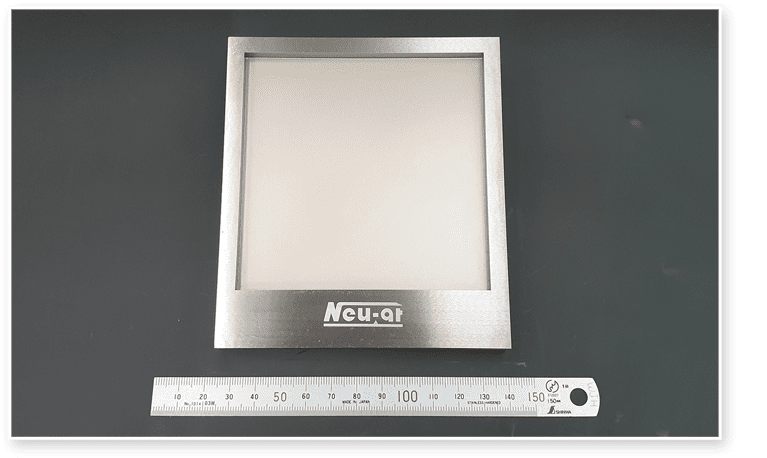

Workpiece

| Item | Content |

| Electrode | Graphite POCO EDM 200 |

| Workpiece | SKD 61 |

| Projection area | 100 x 100 mm |

| Machining depth | 5 mm |

| Machining time | 6 hours 21 minutes |

| Surface roughness | VDI 18 / Ra 0.8 um |