250mm Long Semi-Conductor IC Packaging mold

Core Technology of Automated High-Speed Electrical Discharge Machine

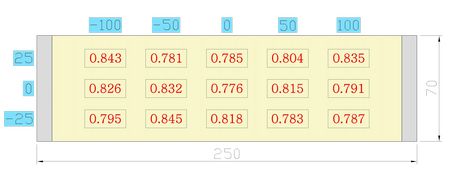

IC packaging molds equipped with the AE II large-area fine machining circuit deliver stable and high-speed processing results. Under these conditions, the overall surface roughness of the IC packaging molds can be consistently maintained within a ±10% deviation from the target Ra value.

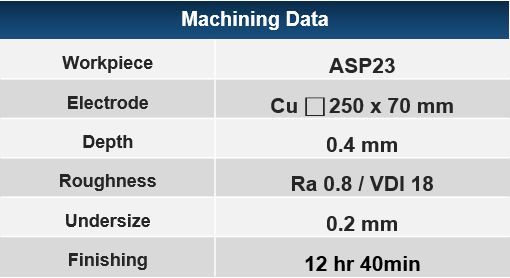

Machining Case Study

Latest Gap Control Technology

- Equipped with "Large Area Finishing circuit(LAF)", can achieve stable and high machining speed in large area.

- High Stability: Precisely controls the discharge gap to ensure a smooth and uninterrupted processing.

- High-Speed Processing: Enhances efficiency and shortens processing time.

- Consistent Surface Quality: The overall roughness in large-area processing can be consistently controlled within a ±10% deviation from the target Ra value.

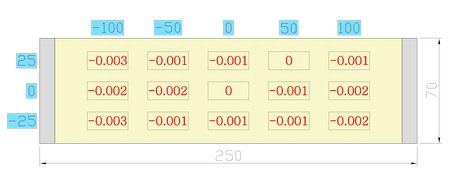

Flatness within 5 μm

Exceptional precision machining capability, meeting the extremely high accuracy requirements of semiconductor processes.

The most suitable surface texture for semiconductor packaging

- The expert system is equipped with intelligent processing capabilities for semiconductor multi-hole machining requirements:

- Automatic selection of the optimal processing conditions: Based on the processing area, it automatically matches the most suitable parameters without the need for manual adjustments.

- Simplified operation process: Reduces setup time and improves processing efficiency. This module is specifically designed for semiconductor processing, ensuring stability and high performance, allowing you to focus on your core production and easily achieve high-quality results

250mm Long Semi-Conductor IC Packaging mold | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction