45° injection hole (sprue gate) in mirror surface

Core Technology of Automated Electrical Discharge Machine

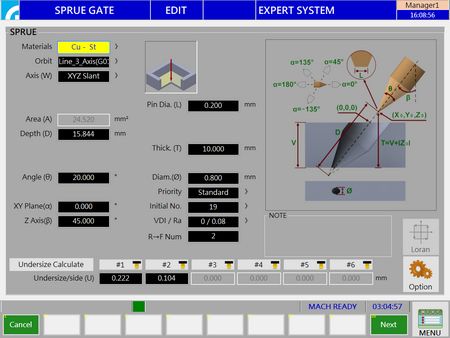

NEUAR Electrical Discharge Machine equipped with the AE II system feature a dedicated "SPRUE" module, specially designed for the machining of mirror-finish angled gates.

This module delivers exceptional stability and performance, making it ideal for precision mold applications.

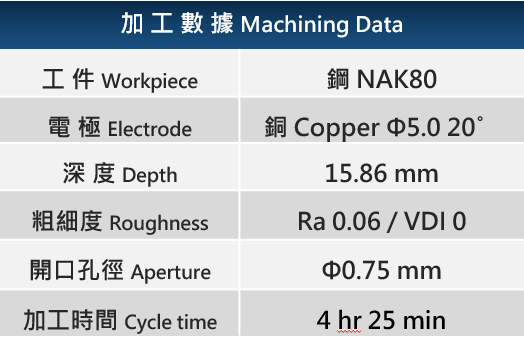

With intelligent automation and expert system integration, the AE II system can achieve mirror-finish surface roughness as fine as Ra 0.06 μm on flow channels. Whether it’s Z-axis linear machining or complex 3-axis simultaneous machining, the AE II system automatically generates machining programs via its expert module.

Furthermore, with integrated C-axis functionality, users can effortlessly adjust the machining angle and positioning, offering a highly efficient and accurate solution for injection gate production in plastic mold manufacturing.

Machining Case Study

Non-Vertical sprue gate machining, no more flip the Mold

Still relying on sine plates to machine injection holes?

NEUAR’s Expert System breaks through traditional limitations. It not only handles standard 90-degree vertical gates with ease, but also precisely machines angled injection gates. By automatically calculating 3D spatial coordinates, the system eliminates the need for tedious mold flipping, delivering a more efficient and flexible machining solution.

gateholesamplebysinkerEDM.jpg)

「SPRUE」Module

The NEUA AE II System is equipped with a dedicated "SPRUE" module, making programming and machining more convenient than ever.

Unlike other brands that require manual input of start and end coordinates—often relying on external CAD software for calculations while ignoring spark gaps, leading to poor machining control—the AE II System is designed to meet real-world needs.

Simply input the desired hole diameter, and the system will automatically calculate the 3D machining coordinates, precisely accounting for spark gaps. The result: a more accurate and efficient machining experience.

Machining Case Study : 45° injection hole in mirror surface

45° injection hole (sprue gate) in mirror surface | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction