Tungsten carbide machining

Core Technology of High-Speed Mirror Electrical Discharge Machine

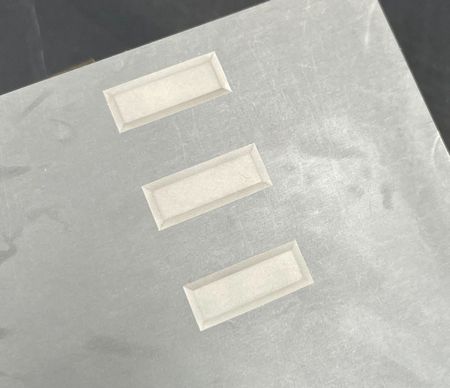

To address the challenge of high electrode wear during machining of ultra-hard materials, the dedicated hard alloy circuit was developed. This technology effectively reduces machining loss and ensures that even the finest sharp-angle details are clearly defined, meeting the demands of high-precision mold manufacturing.

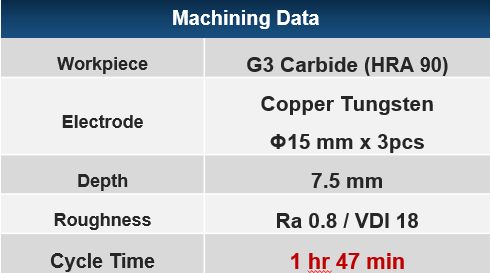

Machining Case Study

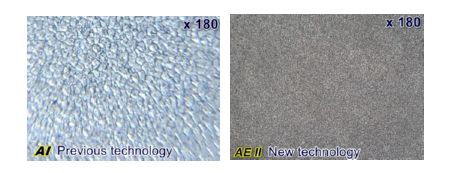

Super fine finishing surface machining no cracks on the surface

Equipped with AE II "Super Hard Tungsten Carbide Circuit (SH2)" achieving an optimal surface finish up to Ra 0.2 μm. Ultra-fine discharge sparks ensure a smooth and uniform tungsten carbide surface with no cracks

Any electrode materials can do it !

Whether with copper, chrome copper, or copper tungsten, the system will optimize parameters for the fastest machining speed with minimal wear!

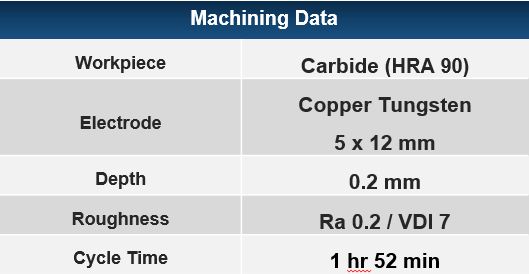

Machining Case Study : Tungsten Carbide Ra 0.2 Super Fine Finishing Surface Machining Data

Tungsten carbide machining | Founded 1998 — Precision Systems, AE II Guidance & Global Support

NEUAR EDM designs high-speed, mirror and automated EDM solutions backed by a team with 40+ years of cumulative know-how. Our AE II Intelligent Expert System streamlines programming so manufacturers reach stable accuracy faster.

From mirror-finish surfaces around Ra 0.06–0.20 µm to reliable micro-radius features, our technology supports mold & die, medical, aerospace and automotive programs with consistent quality and throughput.

We provide structured training, responsive after-sales service and lifetime paid support for mirror EDM systems to protect uptime across global installations—ask about demos, sample cuts or a factory visit.

Company Facts in Numbers

0

Years of EDM Experience

0

Accuracy Assurance (Years)

0%

Client Satisfaction